◉ IIndustrial Case Study

Regional Logistics Optimization: Honduras & Acajutla Case Study with Every Solution.

Redefining efficiency through integrated TOS deployment and Procurement Trade Desk (PTD) services in high-complexity Central American trade corridors.

Verified Performance Results

The Challenge

Operating within the Central American corridor, particularly in Honduras (Puerto Cortés) and Acajutla (El Salvador), presented a set of unique operational hurdles. Terminal operators faced fragmented procurement systems, manual documentation workflows, and high compliance risks that frequently led to vessel delays and increased OpEx.

Key bottlenecks included:

- High volatility in local fuel procurement rates due to lack of real-time market transparency.

- Manual Terminal Operating Systems (TOS) resulting in 15% discrepancy in inventory tracking.

- Extended payment settlement cycles averaging 22 days, straining vendor relationships.

The HSO Solution

Strategic Integration of PTD & TOS

HSO Terminals deployed a unified digital infrastructure that bridged the gap between procurement and physical operations.

PTD Desk Implementation

Established a dedicated Procurement Trade Desk to leverage regional volume and negotiate standardized rates for maritime terminals.

Cloud-Native TOS

Automated gates, real-time tank gauging, and terminal dashboard integration for 24/7 visibility from any location.

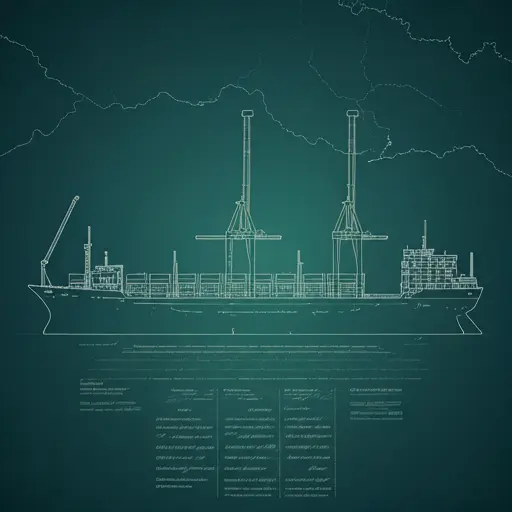

Technical Infrastructure & Terminal Specifications

Detailed engineering breakdown and operational capacities for high-throughput maritime petroleum assets. Verified API 650/653 compliant infrastructure with fully automated Terminal Operating Systems (TOS).

Storage Capacity

01

Loading

Rack

02

Vapor Recovery Units (VRU) active on all bays. Automated driver identification and custody transfer printing.

Port

& Berth

03

Flow Logistics

04

Variable Frequency Drives (VFD) equipped for precise flow control and surge prevention during startup/shutdown.

Safety

& Fire Suppression

05

- NFPA 11/30 Compliant Foam Injection

- Redundant High-Level Overfill Protection

- Automated ESD (Emergency Shut-Down)

- 500,000 Gal Dedicated Fire Water Tank

- Dual Diesel-Driven Fire Pumps

- 24/7 Centralized Monitoring Center